Biomaterial Experiment: Kombucha

The bacterial cellulose (BC) or Scoby, formed during fermentation of kombucha is one of the research subject because of their potential as sustainable biomaterials. The ingredients for fermentation includes SCOBY, sugar and warm tea. During the process, the yeast converts sugars into alcohol, while the bacteria convert alcohol and sugars into organic acids and cellulose. At the end, a layer of bacterial cellulose grows at the surface within a few weeks, based on the sugar content and environmental conditions such as temperature, Ph and O2 levels.

For the experiments, I bought a healthy SCOBY (left in the plastic container) from online.

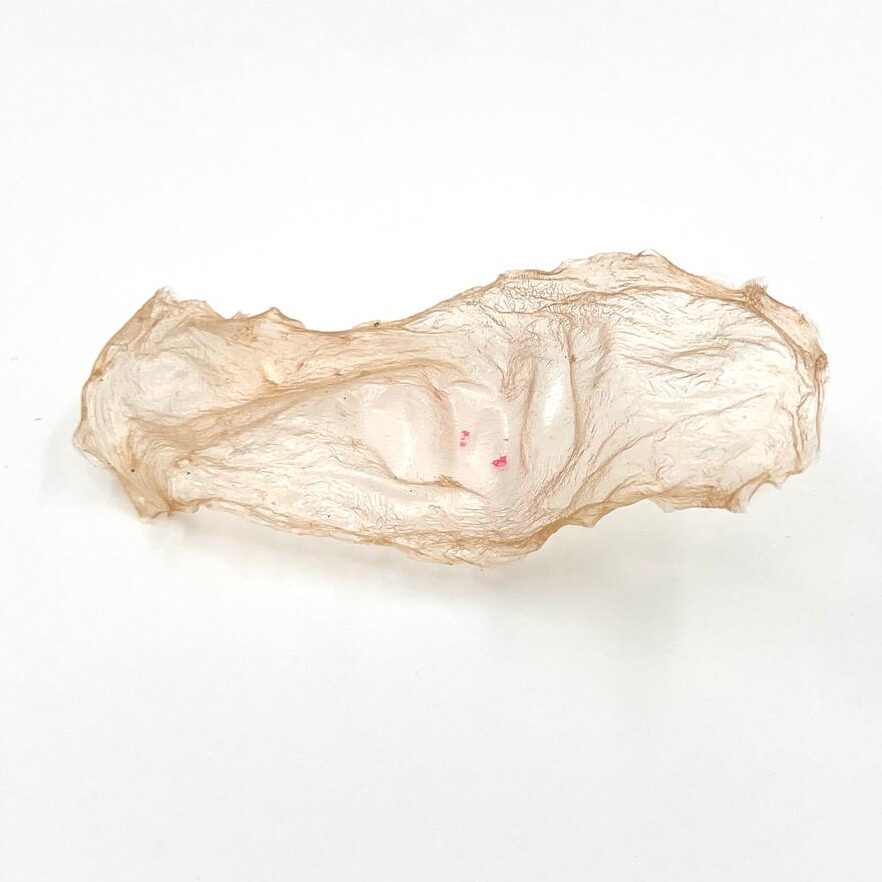

I created an environment with; 1lt warm water, 4 black tea bags, and 50gr sugar inside a large glass jar for the baby SCOBY to develop. After the fermentation, the baby SCOBY (right in the plastic container) appeared at the surface of the jar. Then, I repeated the same process with the plastic container in the image. You can see the bacterial cellulose take the shape of the fermantation container.

Kombucha is easy to make, and cost effective method for biomaterial making process, yet it requires a lot of time to grow a proper Scoby. Even tough the cellulose layer looks thick and flexible, after dries in the room temperature and the water inside evaporates , it becomes transparent, thinner and fragile. Thicker cellulose layers showed the same results in terms of fragility, but with less transparency.

Biomaterial Experiment: Agar Agar

For this experiment, the main ingredient was agar agar which is a natural polymer derived from red algae, used in the culinary and microbiology. It consists mainly of polysaccharides, making it an excellent biodegradable alternative to petroleum-based plastics. Due to its non-toxic, renewable, and biodegradable nature, agar-agar is an ideal candidate for producing sustainable bioplastics.

Ingredients of the Experiments:

- Agar-Agar Powder (1 teaspoon)

- Water (500 ml)

- Glycerin – optional (2 teaspoon)

- Olive Oil – optional (1 teaspoon)

- Red, Liquid Food Coloring – optional (1-2 drop)

Process:

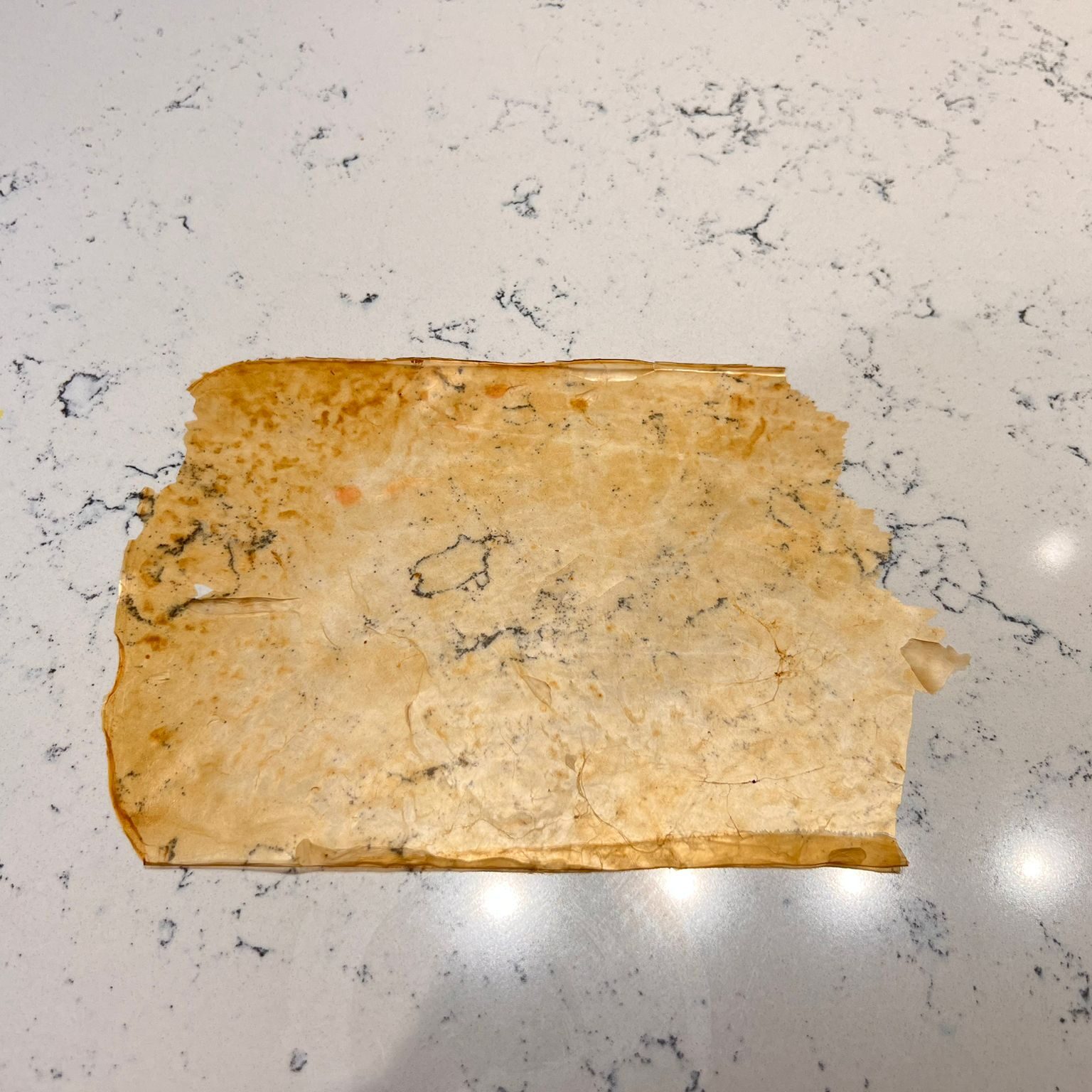

After mixing all the ingredients, you need to heat the mixture and stir it thoroughly until it boils. When the mixture become thicker and gelatinous, you can pour it into a mold or a flat surface. Then, let it to dry at room temperatures for few days.

A polymer is a large molecule composed of many smaller, repeating units called monomers, which are chemically bonded together in long chains. In this experiment, agar-agar serves as a natural polymer and plays a key role in forming the structure of the bioplastic.

I observed that increasing the amount of agar-agar in the mixture made it thicken more quickly and form bioplastic faster. Glycerin acts as a plasticizer, making the material more flexible. The more glycerin is added, the more flexible the final material becomes. Olive oil also contributes to the texture, giving the bioplastic a softer and slightly oily feel.

Biomaterial Experiment: Gelatin

For this experiment, I used the gelatine which is also a natural polymer made of long chains of amino acids. It is the main structural ingredient for the plastics’ shape and strength.

Ingredients of the Experiments:

- Gelatin Powder (3 teaspoon)

- Water (500 ml)

Process:

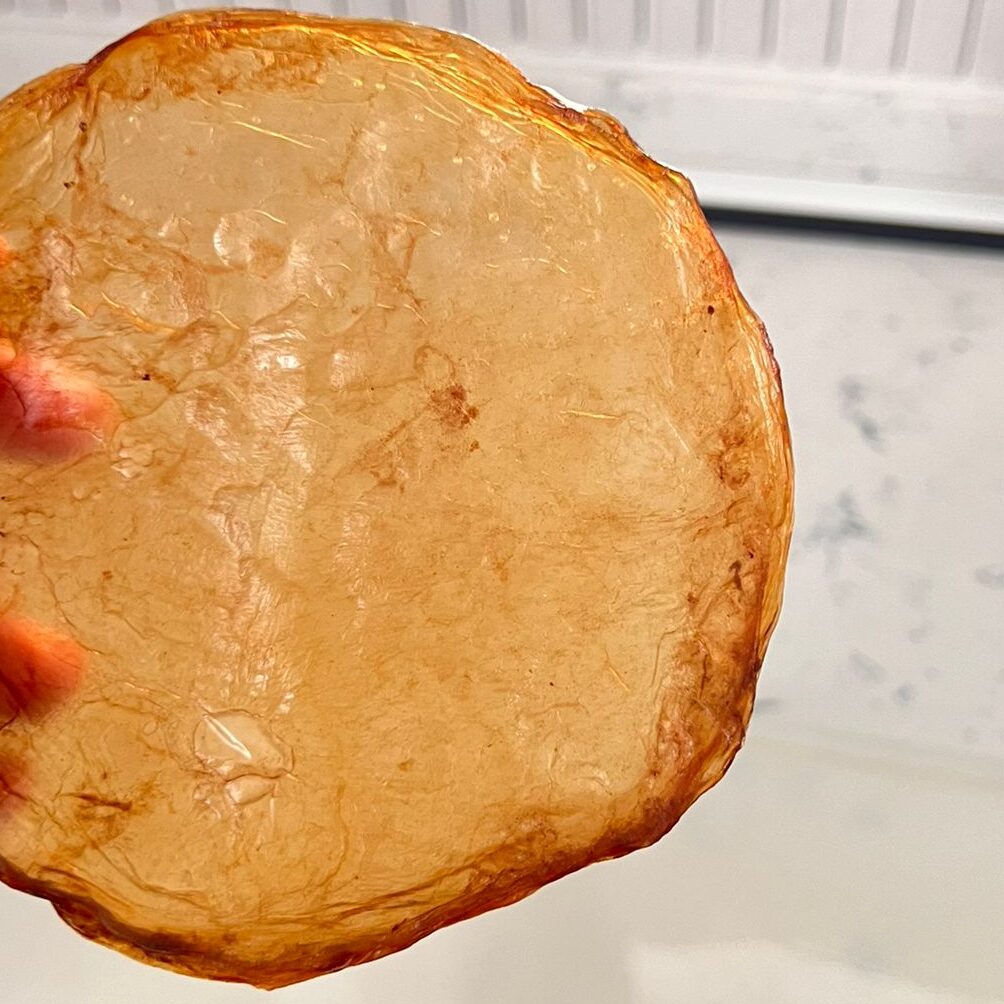

After mixing glycerin with water, heat the mixture and stir it until it boils. When the mixture become thicker and gelatinous, you can pour it into a mold or a flat surface. Then, let it to dry at room temperatures for few days. It shrinks and gets smaller as the water evaporates. Since I did not use glycerin, it becomes fragile, yet stronger than scopy experiment.